A. Flying Shearing Crank Type

Aside from Commercial Length Cutting Shear, others include Start/ Stop type design – controlled through PLC system and provide very close tolerance of the cut length. Used in Hot Rolling Mills to Crop Front/Tail ends, Cobble Cutting in case of misroll, Cooling Bed Length Cutting as well as Commercial Length Cutting.

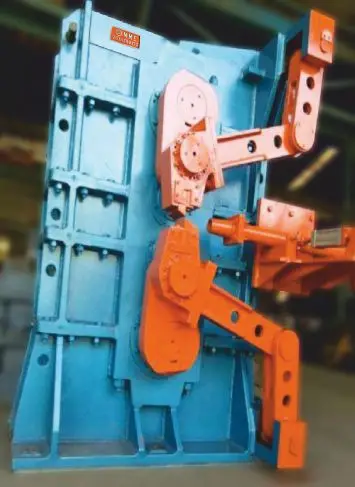

B. Crop & Cobble Shear

The Shear are used in Hot Rolling to Crop Front End, Tail End and as well as to segment cutting in case of eventualities. These Shears are start/stop type and are driven either with Flywheel mounted Pneumatic Clutch/Brake or Direct DC motor driven. These shears are controlled through PLC System small and provide very close tolerance of the cut length.

C. Cold Shear

Cold Shearing machines are used to cut the finished product into desired lengths. We manufacture crop shearing machine for all kinds of Bars, rounds and structural products.

D. Snap Shear

Pneumatic Snap Shears are used for cutting the material while transfer or miss roll in Intermediate Mill, complete with cylinders and solenoid valves. The welded steel frames of Snap hear ensure durability and reliability. These corrosion resistant machines are sturdy and have excellent loading capacity.

E. Rotary Shear

These cost effective Rotary Shears are used to Crop Font, Tail and as well as to scrap the pre quenched bars during emergency. These Shears are continuous rotating type. Generally these Shears are used to trim Hot Rolled Bars at considerably at lower speed.

F. Continuous Shear

These cost effective Rotary Shears are used to Crop Font, Tail and as well as to scrap the pre quenched bars during emergency. These Shears are continuous rotating type. Generally these Shears are used to trim Hot Rolled Bars at considerably at lower speed.

G. Moving Rotary Shear

Hot cut Front /Back end shearing machine is heavy duty fabricated steel construction. The frame is made out of thick steel plates, precisely machined to host 450mm P.C.D. helical pinion gear set. The extended input end of one of the pinion shafts is connected with Induction Motor by means of speed reducing pulleys. The output end of the pinion shafts hosts a pair of rotary blades as specified above. The rotary movement of the blades is responsible for the cutting action as these are interconnected to a pneumatically operated lever

H. Hydraulic Shear

Hydraulic Shear are designed with their high strength capacity to cut metals which are produced in different shapes and sections and it is located right after the Cooling Bed. Hydraulic Shear are manufactured in 2 different ways. Beside this, cold shears can also be designed and manufactured in different characteristic of special projects, when requested. Our cold shears have been preferred thanks to many years of trouble–free operational performance.