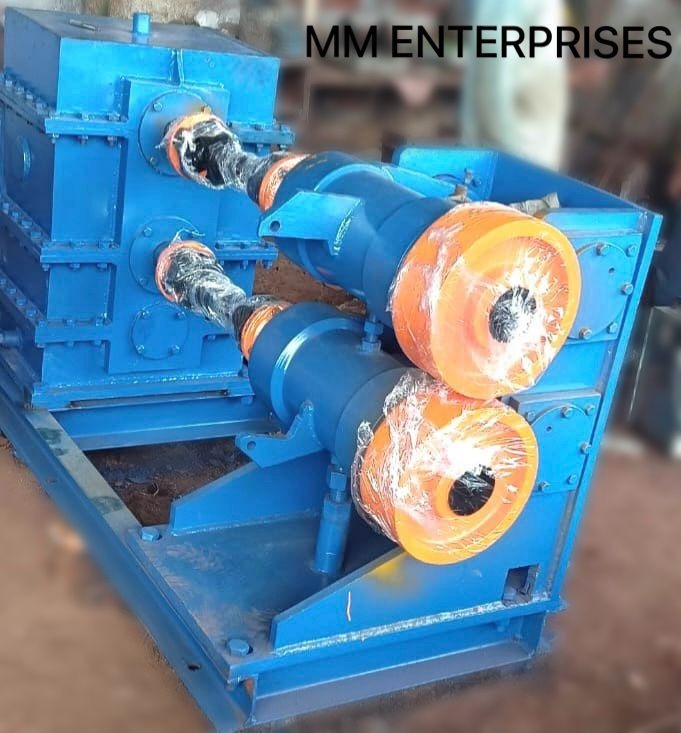

The Pre and Post Pinch Roll systems are essential components in modern rolling mills, designed to facilitate smooth handling and accurate guidance of hot or cold rolled materials. These robust, high-performance mechanisms ensure consistent tension control and material alignment during the rolling process, thereby enhancing operational efficiency and product quality.

Pre Pinch Roll

The Pre Pinch Roll is typically installed before the mill stand or the finishing section. It plays a crucial role in:

Feeding the material into the mill stand with consistent speed and pressure.

Maintaining proper tension between upstream equipment and the rolling mill.

Preventing material slippage, ensuring smooth and controlled entry.

Aligning the strip precisely for optimal processing.

Pre Pinch Rolls are generally motorized and may include hydraulic or pneumatic actuators for precise positioning and control.

Post Pinch Roll

Installed immediately after the rolling stand, the Post Pinch Roll is designed to:

Pull the material through the rolling mill, ensuring a consistent exit speed.

Control strip tension, aiding in the cooling or coiling process.

Direct the processed material toward the run-out table or downstream equipment.

Assist in tail end handling, reducing chances of material looping or breakage.

Post Pinch Rolls are crucial for finishing line stability and are often synchronized with speed control systems to match line requirements.

Key Features

- Heavy-duty construction suitable for high-temperature environments

- Motorized or hydraulic adjustment for roller pressure

- Variable speed drive integration for process synchronization

- Options for vertical or horizontal mounting

- High wear-resistant rollers for extended life